Usually it is a special compartment in which there is a special multi-layer fibrous material that is capable of absorbing a huge amount of ink. The device of inkjet printers is such that the printer "drains" part of the ink to ensure and maintain high-quality printing.

#MPTOOL CANON MP 280 PC#

It happens that one day a message appears on the PC or on the printer display “error X contact service center» Or, in another way, it is called an overflow of the diaper counter. Owners of inkjet printers or MFPs sooner or later came across such a concept as an overflow absorber. Close ServiceTool, turn off the printer, disconnect the USB cable (if necessary).ĭelete the printer "copy 1" that has been installed in the service mode from the "Printers and Faxes" folder (if it is installed). In the program window, in the "Clear ink Counter" section, click "Main" (if necessary, and "Platen") - the counter will be reset to "0"Ĩ.

#MPTOOL CANON MP 280 INSTALL#

The computer will detect a new printer and offer to install a driver on it - refuseħ. If the USB cable was disconnected, it will not hurt to connect it before starting ServiceTool. What exactly is the error can be clarified here: In the case when, instead of a solid green light, the yellow indicator blinks, or blinks with green - the printer has an additional error, which must be eliminated before working with the service program. The indicator will blink green several times, then green will light up continuously. When the power indicator lights up, release Resume (keep it pressed) and press it twice (for each press, the printer should react by switching the indication: the first press from green to yellow, the second - from yellow to green), then release both buttons. Without releasing the Resume button, press the ON button (keep both buttons pressed).ĥ. Press and hold the Resume button, indicated by the triangle in the circle.Ĥ. Turn off the device with the button (do not disconnect the power cord, the device must be connected to the computer via USB).ģ.

#MPTOOL CANON MP 280 DOWNLOAD#

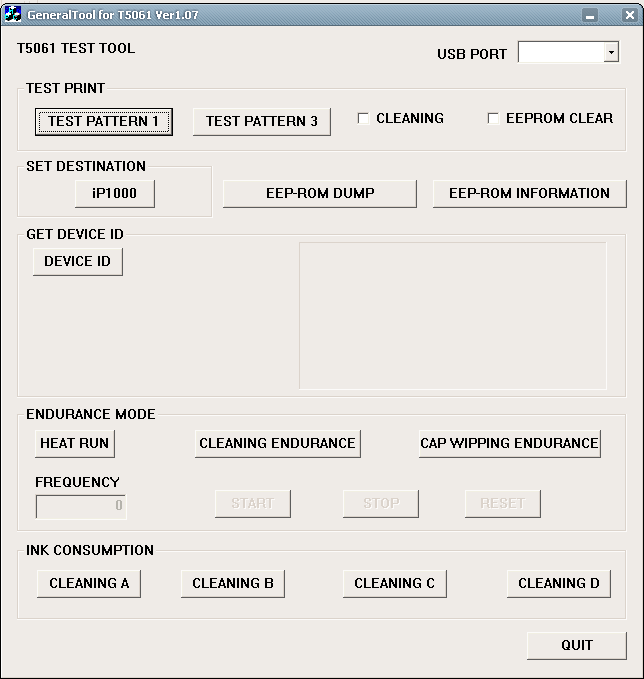

Download the service program ServiceTool_V2000.Ģ. The sequence of actions to reset the counter:ġ. In this case, it is sufficient to reset the absorber counter.įor the Canon MP 250 printer, the absorber counter is reset using the ServiceTool_V2000 utility program.

As practice shows, when the counter is initially triggered after a short operation of the printer, the absorbent material is not yet very dirty and does not interfere with the operation of the device. Because the, given error arose for the first time, the physical washing of the absorber with disassembly of the apparatus is not required. In your case, the system warned you about the imminent filling of the absorber with error E8. It is this counter that is triggered when the ink reaches the set value, and blocks the operation of the printer.Ĭontinuing printer operation requires service, flushing the diaper and resetting the absorber counter to zero. To prevent overfilling, the absorber is equipped with a counter that monitors the ink level. When the absorbent material is filled with the selected ink, the container fills. The absorbent material in the absorber has a certain service life. This capacity is called an absorber (or diaper). The selected ink is discharged into a special container, which contains an absorbent material. To prevent contamination of the print head and ensure continuous high-quality printing, printers are equipped with special mechanisms that include a pump to suck out a small portion of ink.

Accordingly, ink also dries easily in the nozzles of the printer's print head. Modern inkjet printers use fast drying ink for printing. To make it clearer what we are talking about, you need to imagine a device called an absorber, and what it is used for. However, when the absorber counter reaches 100%, the MFP will be locked and will not work until the counter is reset. To continue working, you must press the "Resume / Cancel" button. In Canon MP 250 devices, such an error occurs as a warning from the system that the fill counter of the waste ink absorber has reached 95%.

0 kommentar(er)

0 kommentar(er)